Knowledge of single strand length of stranded thread

The length that a single strand of a stranded line moves due to the twisting of the strand when rotated 360° longitudinally along the stranded line. For electrically stranded wires used as conducting cables and having, for example, as few as dozens of single strands, the skein is several centimeters. For copper stranded wires with 7 to 19 single strands in the 0.2mm diameter range, the skein is usually approximately 15 to 40mm, especially about 20mm.

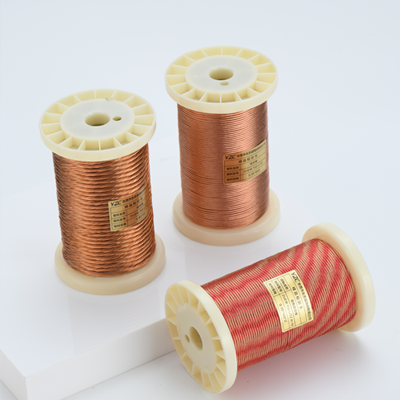

Twisted wire refers to a multi-core power cord formed by twisting multiple copper or aluminum wires together in a circular spiral according to certain rules and directions. Stranded wire: also called multi-strand wire, refers to the multiple strands of the same specification of single enamelled wire tightly concentric stranded, each layer of the twist alternately reverse. Breakdown voltage test of enameled stranded wire: Fold each sample with a length of 500MM in half and twist it according to Table 1. After twisting, cut both ends of the sample and leave a middle length of 120MM. The end of the wire is divided into two parts according to the number of strands, with one end in open state and the other end soaked in tin as the measuring end. One piece of the tin dipping part is clamped with a positive pole, and the other piece is clamped with a negative pole. Then the switch of the instrument is turned on for testing, and the voltage is uniformly increased until the sample paint film breaks down. At this time, the value displayed on the instrument is the voltage value of the sample. Resistance test of stranded wire: stranded wire length can not be determined due to the factor of stranded distance, so the resistance can only strictly control the resistance of a single enamelled wire before production. The conductor diameter of single strand enamelled wire must be strictly controlled in the production process to prevent the conductor of enamelled wire from shrinking. The outer diameter of the three-layer insulated wire is larger than that of the enamelled wire, that is to say, in the same slot, the enamelled wire can be wound 100 times, the three-layer insulated wire may only be wound 60 times, to ensure the number of winding coils, or even need to change the groove.